Here is the link to ITP sensor report

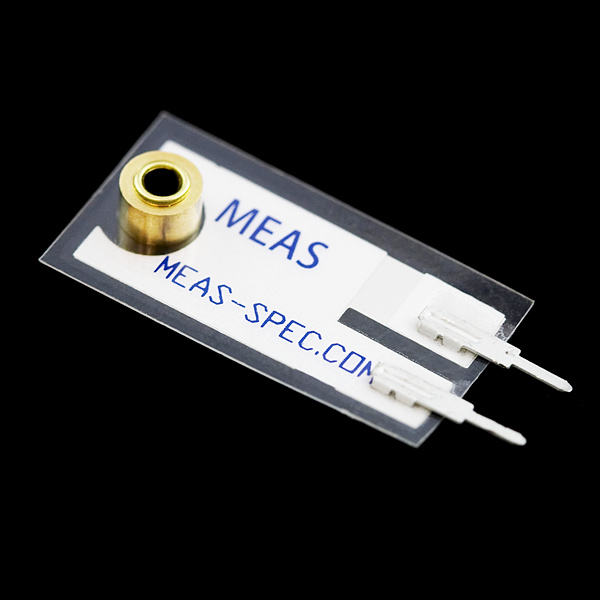

Description

Piezo sensor is often used for flex, touch, vibration and shock measurements. A small AC and large voltage (up to +/-90V) is created when the film moves back and forth. A simple resistor should get the voltage down to ADC levels. Can also be used for impact sensing or a flexible switch.

Where to find them

You can buy it on Sparkfun, Digi-Key and you can also DIY from DIY Sensor Film Kit – 4×6″ adafruit also the readymade piezo acoustic instrument trigger from here

Data Sheet

Data sheet for can be found here and Technical manual can be found here

The basic electrical characteristics, from the data sheet, are as follows:

Power Requirements: N/A

Communication: Analog (Up To ~70 VDC; Sensitivity 50 mV/g)

Dimensions: .98 x .52 in (25 x 13 mm)

Operating Temperature: +32 to +158 °F (0 to +70 °C)

Structure

-DT Series Elements

The DT series of piezo film sensors elements are rectangular elements

of piezo film with silver ink screen printed electrodes. They are available

in a variety of different sizes and thicknesses.

Lead attachment is accomplished using a riveted lug going to 12” (300mm) of 28 AWG wire. The DT film element produces more then 10 millivolts per micro-strain. The capacitance is proportional to the area and inversely proportional to the thickness of the element. The DT elements are supplied with a thin urethane coating over the active electrode area to prevent oxidation to the top surface of the silver ink.

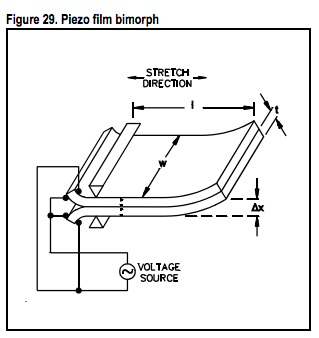

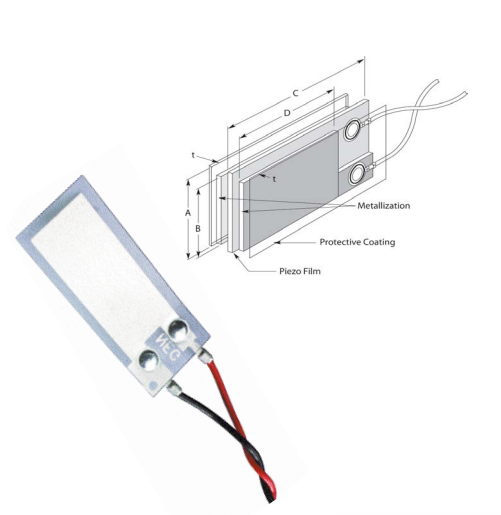

-LDT Series Elements

The ‘L’ in LDT stands for ‘laminated’ sensor. Typically, a 0.005” (125µm) polyester layer is laminated to a 28 µm or 52µm piezo film element. When used in a ‘bending’ mode, laminated film elements develop much higher voltage output when flexed than a non-laminated DT elements series. The neutral axis is in the laminate instead of in the film so the film is strained more when flexed.

Typical Applications for Piezo Film Sensors

Accelerometer

ACH-01 (General Purpose)

-Motion (Theft) Sensors

-Shipping Damage

-Machinery Monitoring

-Motional Feedback for Speakers

-Appliance Monitoring

ACH04-08 (Multi-Axis)

-Disc Drive Shock Sensing

-Impact Switching

-Seismic

-Biomedical Monitoring

Vibration/Motion Film Sensor

DT Series (Unlaminated, Unshielded)

-Dynamic Strain Gages

-Acoustic Pickups

-Musical Instrument Triggers

-Tamper Detection

LDT Series (Laminated, Unshielded) & LDTC

-Antitheft Alarm

-Vending

• Dispensing Verification

• Coin Drop Counters

• Antitamper

• Penetration Panels

-Fan Failure

-Application Monitoring

-Washer Imbalance

-Microwave – Sound Pickup

-Dishwasher Spray Arm

-Water Flow Sensor

-Vacuum Soil Sensing

SDT Series (Unlaminated, Shielded)

-Musical Instrument Triggers

-Contact Microphones

Custom Sensors

-Textile Sensors

-Medical Monitoring

• Patient Bed Monitor

• Pulse Counter

• Fetal Heart Monitor

• Apnea Monitoring

• Anesthesia Monitor (SleepDisorder)

• Respitory Air Flow

• Sleep Disorder (REM)

• Pacemaker Activity Monitor

-Penetration/Antitamper Panels

• PCMCIA Cards

• Data Storage DevisesAudio/Acoustic

-Microphones

•Dive Helmets

•Gas Mask

•Contact

-Stethoscope

-Acoustic Pickups

-Flow Sensors

-Speakers

•Novelty Consumer

•Tweeters

•Pagers

Ultrasound (40 kHz & 80 KHz)

-Air-Ranging Proximity

-Medical Imaging Catheters

-Phased Array

-Acoustic Emission

-Level Sensors (Inkjet, toner)

-Robotic Tactile Sensors

-Variable Force Sensors

-Digitizers

Switch

SW100 Series

-Pinball Impact Switches

– Gaming Machine Switches

– Utility Meter Counters

Custom Switches

-Vector Switch/Joystick

– CMOS Circuit Wake-Up Switch

-Pacinko Game

-Electronic Piano Keys

-Impact Printer Timing Switch

-Sports Target (Impact)

-Snap Action Switches

-Beam Switch

Piezo Cable

-Step Switches

-Pedestrian Safety Mats (Fence & Buried)

-Perimeter Security

-Antitamper

Traffic Sensors

Series BL

-Vehicle Classification

-Weight-in-Motion

-Speed/Red Light Enforcement

-Airport Taxiway

-Security/Safety

Strengths and Weaknesses

Piezo is easy to use with easy interface with the Basic Stamp, SX, or Javelin Microcontrollers. Can also be used for detecting movement or vibrations even into ultrasound. Such devices can help sense in many practical, real-world scenarios. They are extremely sensitive, low cost and easy to use. Piezo’s have the potential to produce very large AC voltage spikes – ranging upwards of ±50V. Because they produce such high voltages, large resistors are often used to “load down” the piezo sensor in vibration-sensing applications. Zener diodes can also be used to clamp voltages down to safe levels

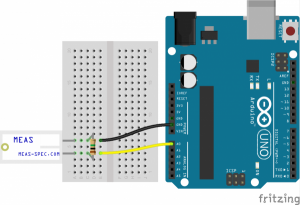

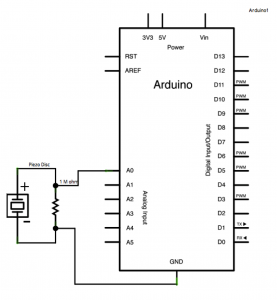

Example Circuit Schematic

here is simple Arduino example code for reading adc

/******************************************************************************

Piezo_Vibration_Sensor.ino

Example sketch for SparkFun’s Piezo Vibration Sensor

(https://www.sparkfun.com/products/9197)

Jim Lindblom @ SparkFun Electronics

April 29, 2016

– Connect a 1Mohm resistor across the Piezo sensor’s pins.

– Connect one leg of the Piezo to GND

– Connect the other leg of the piezo to A0

Vibrations on the Piezo sensor create voltags, which are sensed by the Arduino’s

A0 pin. Check the serial monitor to view the voltage generated.

Development environment specifics:

Arduino 1.6.7

******************************************************************************/

const int PIEZO_PIN = A0; // Piezo output

void setup()

{

Serial.begin(9600);

}

void loop()

{

// Read Piezo ADC value in, and convert it to a voltage

int piezoADC = analogRead(PIEZO_PIN);

float piezoV = piezoADC / 1023.0 * 5.0;

Serial.println(piezoV); // Print the voltage.

}

another example code for piezo vibration monitor . I found from this website

int piezo_Pin= 0;

int LED_Pin= 13;

//Set the threshold levels

int threshold= 500;

//Wakeup the Serial Monitor

void setup()

{

Serial.begin(9600);

pinMode(LED_Pin, OUTPUT);

}

//if the reading is higher than the threshold value, then the LED is turned ON for a Second You can edit to your sepecification

void loop()

{

int reading= analogRead(piezo_Pin);

Serial.println(reading);

if (reading > threshold)

{

digitalWrite(LED_Pin, HIGH);

delay(1000);

digitalWrite(LED_Pin, LOW);

}

}

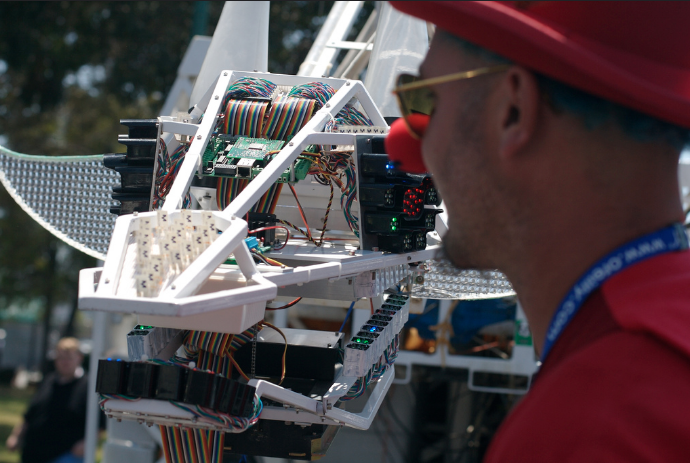

Example project

Electronic Giraffe

Citations

The data sheet is copyright Measurement Specialties, Inc. I found it on sparkfun website. More information on their other products is available on their website.

All circuit drawings were made with Fritzing and modified in Illustrator.